There’s a lot to be said for the satisfaction that comes from creating the perfect bale. Even as technology improves, the thrill is still the same as Jaiden Drought discovers when he tested the Kuhn 2160 BalePack.

There are many great combinations in life — barbecued steak and beer, fishing and beer, and rugby (or any sport for that matter) and beer.

But if you asked a contractor what his favourite combination was (besides anything involving beer), right at the top of the list would be baling and wrapping in one machine. Why? Less time, money, tractors and staff. There literally is no downside.

I recently tested a Kuhn 2160 BalePack run by Clive Pritchard and his team at Pritchard Agricultural Contracting, based at Wairakei, near Taupo in New Zealand.

Kuhn offers two variable-chamber round baler/wrappers, with the only difference being the maximum bale diameter they can produce.

The variable BalePack (VBP) 2160 tested is the smaller of the pair, with 1.2m wide and 1m to 1.6m bales, while the 2190 will produce up to 1.85m. For safety on the hills, the machines come tandem axle with twin-axle braking and 500/45-22.5 tyres are standard.

CONTENTS

Kuhn 2160 BalePack Pickup

I personally think these pick-ups are some of the best on the market in terms of being able to provide constant baling without blockages, even in lumpy conditions with the rotor playing a big part in delivering high outputs and uniform bales.

The main reason for this is the feed augers and the rotor are all one section, meaning you don’t get lumps from the pick-up augers twisting the crop into knots before they go into the rotor and subsequently trip the slip clutch.

Kuhn has just introduced the ‘pendulum’ system to the 2.3m pick-up, where one side is fixed and the other has a slot mounting — so on hillsides the entire pick-up stays parallel with the ground, creating constant crop pick-up, even in challenging conditions. If you do get a blockage, the hydraulic drop floor is controlled from inside the cab.

The test VBP 2160’s both had the 14-knife OptiCut system, where each blade is spring-loaded against any damage and provides a chopping length of 75mm.

This is all controlled from inside the cab and like most knives, will need to be freed with a hammer if left un-used for too long.

Although I didn’t test the knives, the teams tell me the system works extremely well with little difference in rotor performance.

Kuhn 2160 BalePack Bale Chamber

Once the crop enters the chamber, three rollers and five endless belts take over without any problems of bale formation or belts twisting, even in wet sloppy conditions.

Core diameter and a soft-core option are both set from the cab, as are bale diameter and density. Scrapers clean both the belts and rollers and very seldom need cleaning by hand.

All around the property were bales made by these balers from early spring silage, where the grass is naturally shorter and wetter, up until the day I tested it, and there is very little difference — all were firm, well-shaped bales and the operator only needs to allow the on-screen indicators.

The door is held shut by mechanical locks (although a hydraulic option is available) and even with the long stalky grass on the day, crop build up on the chassis was minimal.

Kuhn 2160 BalePack Net Wrap

The baler takes net rolls up to 36cm in diameter and two spare rolls can be carried on the machine. The new roll slides in from the right-hand side of the baler.

The net is fed from the front via a duck bill system and both the roll and its feed into the chamber can be seen from the cab.

Both balers had a considerable amount of net wrapped around the rotor, although I’m told this was pilot error, but given the process is automated, it’s hard to see how this would happen.

A nifty little Kuhn feature allows constant tension to be applied to the net during the wrapping of the bale.

The net wrap system runs at 90 per cent of the bale’s rotational speed, to be able to stretch the net instead of braking. This allows constant pressure on the net, while the guillotine provides an even cut and net presentation was tidy with the shoulders well covered.

The number of wraps is entered on the screen and maintained automatically across different bale sizes. You can also opt to delay net feed until crop flow has stopped, which ensures there are no lumpy looking bales.

Kuhn 2160 BalePack Bale Transfer

Often the bale transfer is where things can go wrong on a combi. Sensors are relied upon to tell the baler to release the bale, transfer it onto the table, shut the door, and start wrapping — a multitude of problems can arise here, particularly on hills.

But the Pritchard boys swear that wherever they can take the baler, the transfer is successful.

Kuhn 2160 BalePack Bale Wrapper

There really is something quite unique about these balers in the wrapping department, and although not a new development, the 3D wrapping has constantly been improved. It may take a little longer to wrap, but looking at these bales, you can tell how it helps appearance.

There is room for ten 750mm rolls on the side of the machine, plus two on the heads, which will allow for a big day baling.

The best feature for me was a slot by the film applicators to place the new wrap end in. This means you don’t have to tie it to anything, leaving a big clump of untidy wrap at the end of the day.

The low-mounted table allows the wrapped bale to be gently discharged while driving, either automatically or manually from the monitor, and both machines came with an end tip kit.

But due to the multi-bale stacking machine, it was more convenient to have them on their rounds.

Kuhn 2160 BalePack Cab and Controls

The test VBP 2160 is ISOBUS-compatible and comes complete with a VT 50 14.5cm colour touch screen monitor.

The graphic shows the bale growing in real-time, which is really impressive. As the bale grows an alert button sounds at 90 per cent and then again when the desired bale size is reached.

The cab display also shows if the finished bale is still on the table.

On hills the bale stayed safely within the cradle, ready for unloading, and both machines were also equipped with a CCTV monitor on the rear. This means you can see the wrapping taking shape and also ensures the transfer and dumping of bales all happens as planned.

For wrapping, the layer number applied is shown in the cab, and you can watch an animation of the process on the monitor (or the camera). If the wrap breaks, an alarm sounds and you can then opt to continue wrapping from one dispenser or fix the problem.

Overall the monitor was one of the brightest and easiest to use of any baler I have tested, with clear readings and, in conjunction with the rear camera, this made operating a breeze.

Kuhn 2160 BalePack Maintenance

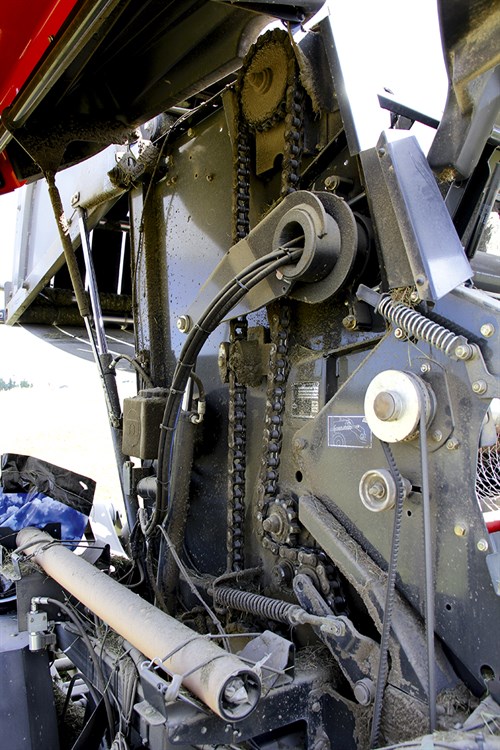

You would think complicated machines have extensive maintenance programs. However, central greasing banks mean all grease nipples are easy to reach, with eight on one side and six on the other, for daily maintenance.

Chain oiling is done from the 4-litre reservoir on the left-hand side and all bar two on the machine are common sensors, which are simple and easy to replace in the paddock if need be.

The Verdict

Bale quality is the thing that stands out for me post-test, as well as just how easy and intuitive the monitor is, making the operation of this machine stress-free.

The 3D wrapping is complicated to explain but watching it in action makes you realise how well the bale is wrapped, with the added benefit of a good-looking end result.

It’s also a very stable baler, even on hills, due to a low centre of gravity and the wide, low profile tyres allowing reliable bale transfer even on steep inclines.

The pick-up is built well and the rotor takes large uneven swaths in its stride.

Variable chamber, nifty net wrap tensioner, reliable transfer and a clever wrapper, which saves film, all in one machine — I told you it was a great combination.

Kuhn 2160 BalePack Specifications

Width 2.99m

Height 3m

Length:6.41m

Weight empty: 5,690kg

Bale diameter (min): 80cm

Bale diameter (max): 160cm

Bale width: 120cm

Pickup width: 230cm

Number of tine rows: four or five

Tine spacing: 61mm

Windguard with roller:Standard

Pneumatic gauge wheels: Standard

Bale formation: five belts plus three rollers

Belt width:215mm

Lacings: Endless

For the full test report, grab a copy of NewFarmMachinery magazine issue 12, on-sale August 11.

Photography: Jaiden Drought