It takes to lot to turn heads in the vegetation management business, says Barry Ashenhurst, but ASV’s RT-120 Forestry Posi-Track loader and Fecon’s Bull Hog mulcher seem to have a head-start

Skid-steer or compact track loaders are popular mulching devices because they’re agile compared with mulching tractors doing the same job. A compact loader will get in and out of tight spaces while a full-size tractor can only scoff doughnuts and watch.

Although not the most efficient combination for tackling large stem sizes, the latest ASV RT-120 Forestry Posi-Track loader, fitted with Fecon’s upgraded Bull Hog mulcher, will push over trees up to 203mm (eight inches) in diameter, and is possibly Australia’s only compact loader with such a focused objective.

It has to be said, though, that application still rules. There’s no such thing as ‘the best compact loader on the market’. Each one has its good and bad features.

Wheeled loaders are better for some applications, but there’s been a swing from wheeled to tracked loaders over the past few years, largely because of their superior stability and lower ground pressures – the latter an advantage when working sensitive ground without creating the damage a wheeled loader might.

|

|

The Fecon Bull Hog mulcher has double-carbide teeth set in a staggered pattern so that only one tooth at a time is actually in contact with the timber. ASV says this setup will handle hardwoods as well as softwoods

|

One company which made a big name for itself with low-ground-pressure earthmoving tools is ASV (All Seasons Vehicles), a company started by former American snowmobile executives Edgar Hetteen and Gary Lemke.

In 1945 Lemke founded Polaris Industries, which became an empire, and in 1961 he founded Arctic Cat, which didn’t.

Then in 1983 he and Hetteen established ASV with a vehicle that combined the most useful attributes of a snowmobile and a tractor. They called it the ASV Track Truck.

Its steering system allowed the operator to individually control dual rubber tracks. The front end could be fitted with either wheels or skis, and it turned out that this hybrid was very good at manoeuvring through the boggy, swampy terrain so characteristic of the Minnesota region.

History is written by winners and I won’t strain your patience by describing what happened after that. Enough to say that ASV produced the Posi-Track rubber-tracked loader in 1991, now lives in Grand Rapids, Minnesota, has a workforce of more than 100, and has cornered a healthy share of the American and Australian compact tracked loader (CTL) market.

|

|

Come to mama. Small stuff doesn’t stand a chance when it reaches the mulcher’s maw. The Fecon is rated to handle stem diameters up to eight inches (203mm)

|

On the job

Vegetation management is an ideal application to test the abilities of a tracked loader, the reason we hooked up for a demo this month with ASV Sales & Service marketing manager Chris Wolf.

ASV Sales & Service is the Australian importer and distributor for Posi-Track compact loaders and Fecon’s range of hydraulic mulchers.

We spent a day watching the combination work a rural plot in the New South Wales Hunter Valley, pushing over small trees then mulching their remains. It was impressive, but the object of the exercise was to find out how ASV improved the latest model – so let’s have a look at that.

The RT-120 replaces the Terex PT-110 and it seems that everything but the famous undercarriage has been tweaked.

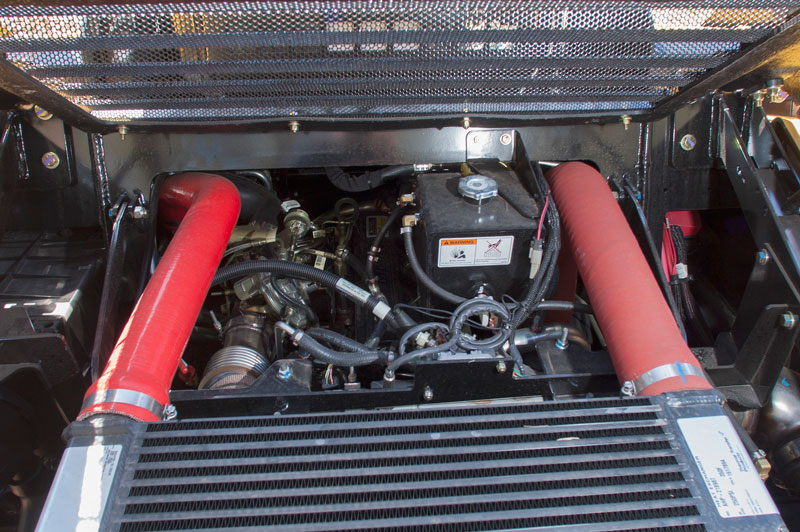

The power plant is now a 3.8-litre Cummins rather than a 3.4-litre Perkins. The new engine is Tier 4 compliant, which means it meets US emission standards. The Perkins was Tier 4 compliant too but the Cummins has 120hp (compared with 111hp) and 488Nm of torque (compared with 450Nm). It’s not a big difference but, as the experts say, you need all the power you can get when you’re mulching.

The chassis is new as well. So is the cab, which now has air-conditioning that copes more easily with sticky Australian summers – no small matter when you’re sitting in a confined space that without decent sealing would be little more than a sauna with windows.

Since mulching invariably generates a cloud of airborne debris, the cabin is pressurised so that fine materials can’t enter your airspace. The engine fan is reversible so woody material that gets past the radiator can be forcibly ejected.

The standard cab has brush sweeps over the bonnet, and guards for the front and rear lights and air-conditioning condensers. In short, Wolf assures me, the Posi-Track is protected from the sort of accidental damage that often occurs in extreme environments where ‘stuff can fall on you’.

General serviceability is improved too, especially to the hydraulic cooling equipment.

|

|

That’s a liquid cooled, 4-cylinder, turbocharged and inter-cooled Cummins QSF3.8 diesel donk

|

Tough hydraulics

Running a high-performance hydro-mechanical device like a mulcher requires equally high performance from the loader’s hydraulic system, a characteristic of the RT-120 that Wolf believes makes it a perfect fit for the application.

“On top of that,” he says, “the hydraulic system is optimised in that the loader is putting out 170 litres a minute while running at 4060psi (27,993 kPa).

“With the combination of high engine horsepower, high flow and high pressure, we think we have the most powerful compact loader on the market, designed for exactly this type of work.”

Wolf goes on to say that, when you’re putting out so much oil at such high speeds, it’s important to keep hydraulic temperatures under control.

“With that in mind, I think ASV has done a good job of engineering the cooling package to suit the application and the Australian climate,” he says. “We did a lot of field work to make sure the RT-120 would operate efficiently in Australia. That was very important.”

But the loader is only half the package. Although the Phase 3, Fecon Bull Hog mulcher still carries the previous mulcher’s BH85SS designation, it too has been upgraded.

It has the largest drum in its class, and staggered, spiral-pattern double-carbide teeth that can process Australia’s legendary hardwoods. The mulching chamber itself has been streamlined to smooth the passage of processed timber.

As you’d expect, says Wolf, mulching soft pine takes less horsepower than chewing up hardwood but with 120hp behind it, high-capacity hydraulics and double-carbide teeth, the Bull Hog is ready to chew ’em all down to mulch.

ASV POSI-TRACK RT-120 FORESTRY LOADER SPECS

Engine: 3.8-litre Cummins

Output: 89.4kW

System pressure low: 22,750kPa

System pressure high: 27,993kPa

Undercarriage: General purpose rubber compound track

Operating weight: 5110kg

Max travel speed: 16km/h