With its 11,200-litre tank capacity; 24 to 40 metre booms and self-steering tandem axle and advanced electronic operating systems, the new Amazone UX11201 Super sprayer is purpose-engineered for fast, safe and easy precision spraying.

CLAAS Harvest Centre Product Specialist – Amazone Joshua Patrick says the new model can be equipped with a range of smart technology, including automatic nozzle selection, active boom guidance system, active vibration damping and section control.

“All of these systems were developed by Amazone specifically to optimise spraying performance while simplifying operation,” he says.

“In its simplest configuration, the UX11201 Super can be equipped with conventional valves for up to 13 part-width sections, complemented by the tried-and-tested DUS pressure re-circulation system.

“The next level up is AmaSwitch individual nozzle switching, which enables 50 cm part-width sections.

“The top-of-the-line specification is the AmaSelect individual nozzle control system.

“Regardless of which system is chosen, all of the key operating functions are effortlessly controlled using the TwinTerminal 3.0.”

The UX11201 Super can be equipped with passive rear axle steering or a fully-automatic twin-axle steering system.

“The latter option is particularly important for row crops, such as potatoes, or smaller paddocks, where track damage can become economically important,” Patrick says.

“During field operation, the first axle follows the tracks of the tractor’s rear wheels, while the second axle follows the tracks of the tractor’s front wheels.

“During road transport, the first axle is locked and the second axle is actively steered by the system.”

The hydro-pneumatic suspended chassis and sprung drawbar ensures smooth operation.

“The axle assemblies continuously adapt to the load conditions,” Patrick says.

“The sprung drawbar has a support load of three tonnes, which is automatically increased to four tonnes when the tank is full.”

Located at the front of the sprayer for easy access, the SmartCentre station makes short work of mixing, filling, spraying and cleaning operations.

“During a function change, all the valves are closed by swivelling the seven-way pressure tap outwards, which allows the tap to be turned to a new position without opening any liquid lines,” Patrick says.

“Once the desired function has been selected, the pressure tap is swivelled inwards, which reconnects the respective valve and circuit.”

The station is lit by LED lighting and protected by a covering hood that prevents the build-up of dirt on the operating taps.

The 60-litre induction bowl is located directly in front of the control panel.

An enormous suction rate of up to 200 L/min ensures fast tank filling and complete emptying.

The mixing nozzle prevents clogging of the extraction opening, so powder or granulated inputs can be easily inducted.

The capacity of the mixing nozzle can be continuously adjusted and be operated in parallel with the new high-output rinse ring that also allows for continuous adjustment of the spray rate.

The canister rinse nozzle has a large support area, on which the nozzle can be activated by pressing canisters or measuring jugs in position.

The top area of the canister rinse nozzle also has a small support area via which the nozzle can be activated to clean the canister neck.

The dust-tight and liquid-tight lid on the induction bowl swivels sideways through 180 degrees when opening and, in this position, with its brackets, it serves as a handy storage for measuring jugs and canisters.

The integrated drainage device means that any residual liquid flows directly back into the induction bowl.

The tank has a low centre of gravity and a compact design.

Two freshwater tanks with a total volume of 900-litres are mounted between the mudguards at an equal distance from the centre of gravity.

“The smooth inside walls of the tank facilitate fast and easy cleaning,” Patrick says.

“Its optimum geometry means that only a tiny residual volume of less than 20 L remains in the tank.”

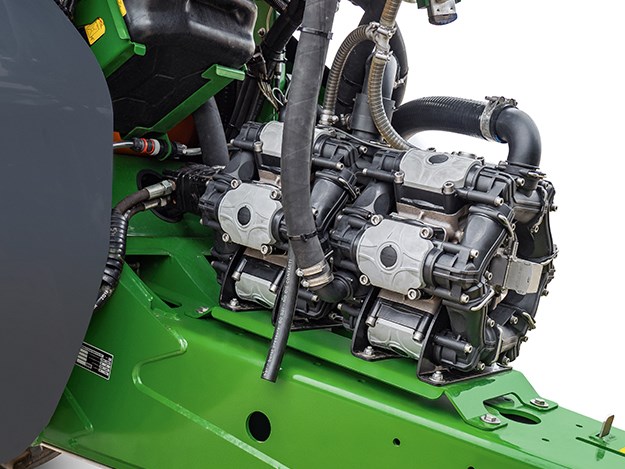

The UX11201 Super has two piston diaphragm pumps with a combined output of 700 L/min.

“These pumps are particularly reliable during operation and are resistant to dry-running and liquid fertiliser,” Patrick says.

“A further practical advantage is their easily accessible position on the drawbar.”

The optional hydraulic drive features an automatic flow adjustment system.

During field use, the pump runs at a gentle 480 L/min, sufficient to maintain agitation and normal application rates.

During transport, the pump speed is automatically reduced to 400 L/min, since only the agitators need to be supplied.

During filling, peak output of 540 L/min is required.

These flow rates are pre-selected by the operator using the terminal and can be changed at any time.

In addition, the pumps can be operated in parallel to double the maximum application rate, allowing high volumes of liquid fertiliser to be applied at higher speeds.

“In vegetable crops, for example, it is possible to accurately apply up to 2000 L/ha at an operating speed of 5 to 6 km/h,” Patrick says.