Agricultural machinery manufacturer Krone has delivered on its promise to bring the world’s first non-stop round baler into the country. TOM DICKSON tracks Australia’s only unit down in South Australia’s Barossa Valley.

SA-based Regari Contracting principal Craig Hage introduced this latest Krone baler into his Barossa Valley-based machinery collection to improve efficiency. His company offers services in broad-acre spraying, seeding and all things related to hay and silage production.

This is after Hage decided to put his successful motorcycle racing days behind him.

During his racing career, Hage suffered his share of physical injuries, estimating he’s either broken or dislocated most of his joints at some time, yet he says the pain of broken bones upset him far less than the frustration of sitting idle in the seat of his tractor, waiting for the baler to apply net wrap and toss out the bale before he could resume work.

It comes as no surprise, then, that he jumped at the opportunity to own the first non-stop round baler-wrapper combination in Australia, Krone’s Ultima CF 155 XC.

Krone Ultima CF 155 XC overview

The Ultima CF 155 XC baler-wrapper combo features an improved camless pick-up with rotor feeder and knife assembly as well as a pre-chamber for continuous operation and loads of new technology.

The bales it produces have diameters between 1.25 and 1.5 metres.

Hage estimates the machine has boosted his hourly production of wrapped silage from 45 to 50 bales per hour to around 80 to 85 bales.

Clearly, his competitive nature and desire for speed are still strong – but never at the expense of the safety of his staff or machinery.

“I am far less mentally and physically drained at the end of the day because there’s little to do but steer the tractor. The baler’s on-board computer does the rest.”

Non-stop process

There are plenty of differences between this new baler and the existing Krone line-up but the most obvious is the fact that it never has to stop.

This one advancement propels the Ultima into a class of its own and solves the age-old issue everyone who has ever operated a round baler has suffered.

It’s a huge step forward yet appears to be a simple design.

While the completed bale is being tied off with net, the incoming crop is fed into and held in the pre-chamber.

When the finished bale is ejected from the baler, the rear door closes, which triggers the pre-chamber delivery belts to re-engage and force the pre-compressed hay or silage into the main chamber where the process begins again.

Pick-up

The camless pick-up operates extremely quietly due to minimal moving parts, and maintenance is virtually zero.

It has a working width of 2150mm and the side augers that feed the crop into the middle seem larger than on preceding models.

Double tines are staggered in a helical pattern, which Krone claims provide a more even feed of crop into the baler, while the pneumatic guide-wheels operate like casters and deal with direction change well and cause no scuffing when turning across the windrow.

Rotor feeder and cutter

An obvious improvement can be seen when looking at the rotor feeder.

It’s massive and has been upsized to boast a 750mm diameter. The increase in size allows it to pump a much larger volume of crop through.

From within the cabin of the tractor, the driver can engage and disengage the knives hydraulically.

The Ultima can be operated with no knives engaged, all 26 knives or just half the knives engaged.

When the one set of 13 knives lose their edge, they can be retracted and the other 13 engaged to ensure a good cut and double the time between sharpening intervals.

All 26 knives engaged provide a 42mm chop, while operating with 13 produces an 86mm chop.

The knife tray slides all the way out the side of the baler, making it really easy to work on the knives.

This process takes only minutes; lower the pick-up, unlock the tray and slide it out. It sits at a comfortable working level, around knee height. Each knife is individually sprung to protect against solid objects that may find their way into the rotor feeder.

On this occasion we are baling straw and there’s no need for chopping, so we’ve removed the knives and replaced them with the supplied blanks which prevent any build-up of dust and straw residue in the knife bar.

If a blockage occurs, the floor of the rotor feed drops down to allow the blockage to be easily drawn into the baler.

Pre-chamber

The pre-chamber is about 1.5 metres long, with rubber delivery belts on the floor and roof of the chamber.

While forming the bale, the belts transfer the crop from the rotor feeder to the main baling chamber.

When the bale is formed and the net wrap starts, the belts in the pre-chamber reverse a bit to take the incoming crop away from the formed bale, then stop.

It’s recommended that the pre-chamber belts are re-tensioned every 500 bales but Hage says he can stretch this out to 1000 if he doesn’t push the baler too hard.

The pre-chamber is undoubtedly the biggest refinement in the new Krone baler and the hay production industry in general.

The baling chamber itself is semi-variable, with two manual adjustment bars on either side of the baler. Six bale diameter options range from 1.25m to 1.50m in 5cm increments.

Wrapping

Once the bale is formed and net wrapped, it’s dumped onto the silage-wrapping table.

These balers are fitted with sonar sensors that detect when the bale has landed on the wrapping table and close the rear door.

Hage found that straw sticking out from a bale or an uneven bale of silage could trigger the sensor prematurely, which then tries to shut the door before the bale has fully exited the chamber, so he reverted to the mechanical system mounted on the floor of the wrapping table.

Up to 18 rolls of silage film can be stored on convenient posts that swing out and deliver the roll at shoulder height.

So without having to lift it, you can slide it off and carry it back to the wrapping table.

A fantastic feature on the silage wrapper is that if one of the two film wraps fails, the baler’s computer will maintain total coverage by doubling the wrap of the operating roll of film.

The net wrap needs no heavy lifting either as a cradle with hydraulic struts lifts the net to the top of the baler and into position. The baler is designed to carry three rolls of net plus one in the dispenser.

Performance

The Krone Ultima wins me over the moment it spits a completed bale out the back, as we cruise along at 10km/h. It further convinces me it’ll be in strong demand every time it repeats the process.

Then we grind to a halt as it starts to have problems net-wrapping the bales – Hage says it’s the first time it’s let him down all season.

The problem began as we switched to baling wheat straw and, after consulting the operator’s manual, we learned there was too big a gap between the cleaning blade and roller, which allowed net to be drawn down and wrapped around the roller.

Once we loosened the blade and repositioned it to within a whisker of the roller, the issue was solved and we were back on our way.

The bolts to reposition the blade were hard to get at, which made what should be an easy job a little tricky and took longer than it should.

Our guess is that the coarse wheat stalks were poking the net down through the gap.

But this is the only issue that appears and as far as I can tell, it’s generally a stress-free machine to operate.

By my count, the Ultima is completing a bale every 45sec and feels like it’s well below what it could be doing, since the crop is disappearing into the front without any sign of build-up.

The unit is operating quietly and even on tight turns there is zero PTO shaft shudder.

The reason why there’s no PTO slap is because Hage has installed a K 80 ball hitch from transport componentry manufacturer JOST Australia.

This provides zero slop at the hitch point and places the pivot point between the tractor and baler directly below that of the PTO shaft universal joint.

He is so impressed with the ball hitch performance he says he is going to install them on all his tractors and implements.

Controls and other features

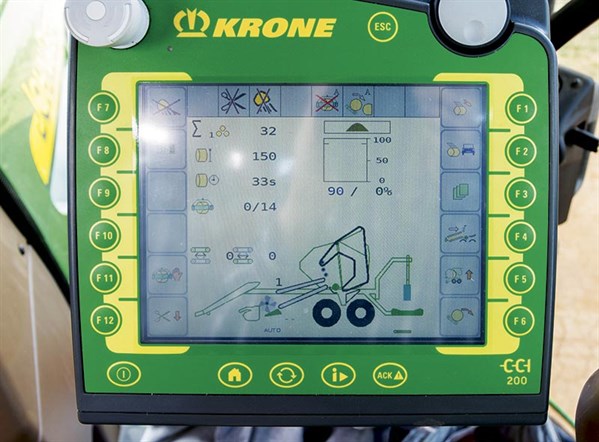

Greasing and oiling are automatic, taken care of via the cabin-mounted CCI Terminal which has Tractor Implement Management (TIM).

When fully implemented, TIM takes control of all of the activities of the baler and can even control the speed of the tractor in uneven windrows.

The only jobs left to the operator are steering, and filling the grease and oil canisters every 1000 bales or so.

The baler is also equipped with a hydraulic leg stand.

LED light bars and on-board cameras allow the operator to see exactly what’s going on in hidden areas both day and night.

Verdict

I predict contractors are going to love this machine for the speed at which it can get the job done.

Equipped to bale and wrap, it allows one man, one tractor and one baler to perform two operations, saving time and money in an already labour-starved industry.

Hage has also successfully trialled the addition of a front-mount mower to the package, allowing him to cut, bale and wrap silage all in one pass.

A strong and sturdy foundation is essential to the quality and longevity of any structure and I’m convinced the Ultima’s chassis is as good as I’ve seen.

The caster-steer tandem axles feature extra-heavy-duty parabolic springs to provide generous up/down cushioned travel while carrying the same load as the rigid design, and are approved for 60 km/h. Big flotation 620/40R22.5 tyres are base specification.

Evolution is a marvellous thing and soon this new breed of baler will be a common sight on farms all over Australia.

Hits:

- Non stop

- Camless pick-up

- Knife tray

- Steer assist

- Self-lubricating

- Emergency stop buttons at rear of baler

- JOST Australia ball hitch

- Camera and light package

Misses:

- Roller knife adjustment

- Bale sensing sonar on wrapping table

Specifications

Bale size

Width mm 1200

Diameter mm 1250-1500

Baler

Length mm 9000

Width mm 3000

Height mm 3900

Weight kg 11400

Camless pick-up

width mm 2150

Tine rows 5

Don’t miss the full review also in the upcoming issue of Farms and Farm Machinery magazine.

Click on the link below to subscribe to the magazine and never miss an issue:

Photography: Andrew Britten | Video: Andrew Britten